| |

3/4" C:B ratio - test day

|

The longest barrel tested was 26' 8" or 320" with a C:B ratio of .14:1. This barrel was 3/4" sch 40 PVC and would be cut down 20% of it's length each time. This barrel was too long and the slug was not able to escape past the muzzle. The slug could reach a point near where the barrel appears to bend in this photo.

|

|

Two 4'x8' tables were set up to support the long barrel. The miniL1 and all it's hoses, wires and switches were then attached to an extra low, heavy duty stand. The slug was not able to exit this 320" barrel but neither was any sound able to escape. Attempted shots with this barrel were nearly silent.

|

|

|

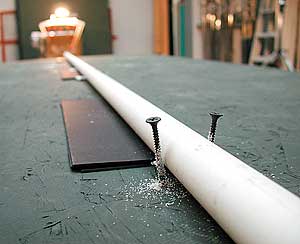

Screws were drilled into the table to help keep the long barrel aligned horizontally. Cardboard shims were placed underneath to account for the connector fittings which elevated the barrel above the table.

|

|

Fuel pressure was checked before each shot. Our new gauges feature 1psi increments and 2% mid-scale accuracy. The combustion chamber of the miniL1 is 373cc and is one and a half times the volume of a 29.5" barrel. This would be expressed as a 1.5:1 C:B ratio. The C:B ratio will be given after each new measurement in the following paragraphs.

|

|

|

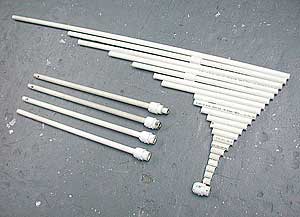

The first cut was made at 256" (.17:1) and was an even 20% off. The slug was still not able to make it out of the barrel. At 256" we were able to accurately measure how far the slug traveled before friction and the vacuum behind it caused it to stop. Both new and used gasket slugs were stopping at approximately 210". The next cut was made at 210" (.21:1) which is only 18% of the length but established an upper limit for our test. Subsequent cuts were done at 20% of existing length.

|

|

The first recorded shots with the 210" barrel were surprisingly fast, up to 181fps. There doesn't seem to be a length where a tight fitting slug will just plop out the end. If there is, we just missed it by an inch. This upper length limit is determined by a number of variables and would be different for each particular ammo and power configuration. By this logic, the fastest ratio might also be particular to each individual setup.

|

|

|

This barrel at 86" (.51:1) was showing improved velocity with readings as high as 486fps. This barrel remained nearly silent despite the high speeds. Only a slight whoosh could be heard as the slug traveled down the barrel.

|

|

Our climb to the top ended with the fastest shots recorded to date with our miniL1, 523.1fps. The top speed was obtained with a 55" barrel which gave a calculated .8:1 C:B ratio. Readings on either side of .8:1 were also high which could point to even faster readings between .7:1 and .9:1. A fine tuning test will be conducted before C:B tests begin on the full sized L1. The L1 has a 2600cc chamber and would require a 8.3' barrel to get .8:1 using 1.5"sch40 PVC. That's a big barrel to carry around for a such a modest sized chamber.

|

|

|

We continued to cut the barrel down 20% at a time to discover a steady trend toward slower speeds. This short barrel is close to 2:1 and provides convenience while still generating speeds above 400fps. One of the most important lessons learned from this test was that when the barrels became shorter than .8:1, the noise from the gun became increasingly louder. It appears the unused energy escapes the barrel in the form of sound.

|

|

This cute number features a 9.25" barrel (4.78:1) and shoots about 310fps. Accuracy is probably not this barrels strong point as many of the tumbling slugs were found lodged backwards into the carpet backstop. These ultra short barrels are ultra loud. Earplugs were required for the rest of the test.

|

|

|

The end of the line was this stub which has 1.75"(25:1) effective barrel in front of the slug. This "barrel" was able to shoot about 170fps and was the loudest barrel tested. The shock wave from the wasted energy could be felt up to 2' from the muzzle. This barrel was the least accurate and actually hit the chronograph wire on one shot. This was the hardest to align with the target as there was no barrel to aim with.

|

|

Doing this test on the miniL1 made sense as the required barrels cost under $20 and the propane used was probably less than $1. Carbon monoxide levels are also lower with the smaller combustion chamber although the indoor shooting range was vented with fans during the tests.

|

|

|

The numbers don't lie. 169 recorded shots were fired during actual testing and another 200 were fired during gasket slug development. One particular C:B ratio did show the highest speeds. The ideal ratio of .8:1 worked for the miniL1 using a refined gasket slug. Will this number translate to a full sized launcher using spuds for ammo? We're not sure but you can bet that we'll test it soon.

|

|

|

|