| |

2.5" C:B ratio - test day

|

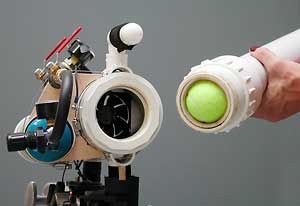

This chamber to barrel ratio test utilizes a 2.5" diameter barrel designed to launch tennis balls. Previous tests with smaller diameter barrels have shown a Chamber:Barrel volume ratio of .8:1 to shoot fastest with low friction gasket slugs while a longer .6:1 ratio shot fastest with russet potatoes. Tennis balls and the large barrel they demand give us a unique combination to add to the existing test data. Pictured here is an L3 launcher with the 12 foot test barrel in place.

|

|

The 3" chamber opening on the L3 allows tennis balls to be breech loaded. They fit tightly inside a 2.5" barrel and load quickly. The tennis balls shot at more consistent velocities than spuds but slightly less consistent than the gasket slugs used in previous tests.

|

|

|

The tennis balls chosen for the test were Penn Court One brand. These are widely available for about 2 bucks a can. The Court One is a recreational ball with a soft core and average durability. The problem with soft or under pressurized tennis balls is that they can deform and let combustion pressure escape past the ball. This is more common on longer barrels and results in slower speeds and an unusually loud report.

|

|

Tennis balls are pressurized at the factory and preserved in vacuum sealed cans. Low quality or defective tennis balls can loose their pressure quickly. When mushy ammo was discovered during this test, the shots were noted and the balls discarded. The Court One brand held up fairly well with brand new balls shooting about the same speeds as the used ones. High quality tennis balls are available which are designed to hold their pressure under heavy use. Special pressureless balls are also available which could provide durability and possibly higher velocities.

|

|

|

The L3 was set up at the test location on a clear summer day. A 5 gallon bucket filled with plastic wrap served as a backstop and worked flawlessly. The chronograph sensor was placed two feet from the muzzle to record the velocities. This is the same basic setup used in all of our past C:B tests.

|

|

We were a little worried that the 12 foot barrel at .26:1 might backfire as did the longest barrel in the 1.5" C:B test. The fan was removed as a precaution and the first shots came in at 284fps and 145fps. The fan was put back in which showed an increase in velocity to 342fps. After that, the 12' barrel started to give some problems. Tennis balls were starting to get stuck about 2 feet from the muzzle. This may have been caused by mushy ammo or simply that the barrel was approaching maximum length.

|

|

|

Pictured here is a brand new tennis ball which has made one trip through the 12 foot barrel. The ball was loaded in the orientation pictured with the X and word TOP visible at the breech after loading. The burn marks are caused by friction alone and also appear on pneumatic launchers. It would appear that this new ball found a comfortable shape inside the barrel and did not rotate while making it's journey to the muzzle. The yellow fibers on the breech side were slightly burnt but the fuzz on the muzzle side was untouched. Burnt tennis balls smell horrible, keep the can handy for storage.

|

|

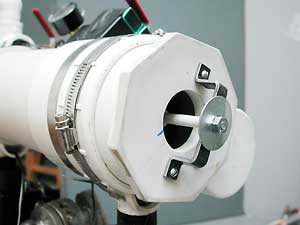

The first cut was made at .3:1. This barrel reduction and heightened awareness of mushy tennis balls eliminated the backfire issue. Tennis balls load and recover from the backstop quickly. This test proceeded at a brisk pace and was completed within six hours. Velocity continued to increase with each successive cut and reached its' peak at .7:1 C:B. As before, the shots at .7:1 and longer were relatively quiet. It was at the shorter barrel lengths that the noise became extremely loud due to the wasted energy. The barrel was only cut down to 1.1:1 as shorter lengths would simply be too loud for our urban test zone. The picture here shows the one way check valve used to vent the chamber. This valve may have helped eliminate backfires at .26:1.

|

|

|

The 4" endcap check valve pictured here was tested extensively before being deemed reliable for this test. Earlier versions had a tendency to leak slightly but revised valves seal the chamber completely. Fluid volume measurements were taken with this valve in place and it did not leak one single drop.

|

|

The hole in the endcap lets less air in the chamber than if the cap was removed completely. Despite this, an 80mm fan still clears the chamber within seconds. Extra run time was given just to be sure venting was complete. The chamber fan ran full time during this test from a 15 volt AC/DC adapter. Mouse over the image here to see the valve in action

|

|

|

Another perfectly good barrel gets cut to shreds. This time the remaining short barrel can serve a good purpose, it's an excellent noisemaker with respectable velocity. The PW brand pipe used here was top quality. Very smooth on the inside and highly recommended.

|

|

|

|